Forge Battery, an innovative company in the field of energy storage technologies, has just announced the launch of wholesale shipping of its lithium-ion battery cells offering an energy density of 300 Wh/kg. This advancement represents a significant step toward improving energy efficiency and sustainability across various sectors, including electric transportation and renewable energy storage solutions. By making these high-performance cells available, Forge Battery aims to support the transition to a decarbonized economy while meeting the growing demand for efficient and accessible energy storage systems. This initiative could transform the energy landscape, promoting the adoption of renewable energies and contributing to the reduction of carbon emissions.

Forge Battery, a commercial subsidiary of Forge Nano, Inc., has officially begun shipping its high-energy lithium-ion 21700 battery cell prototypes to existing customers and potential partners. This advancement marks a key milestone in the development of sustainable and innovative energy solutions.

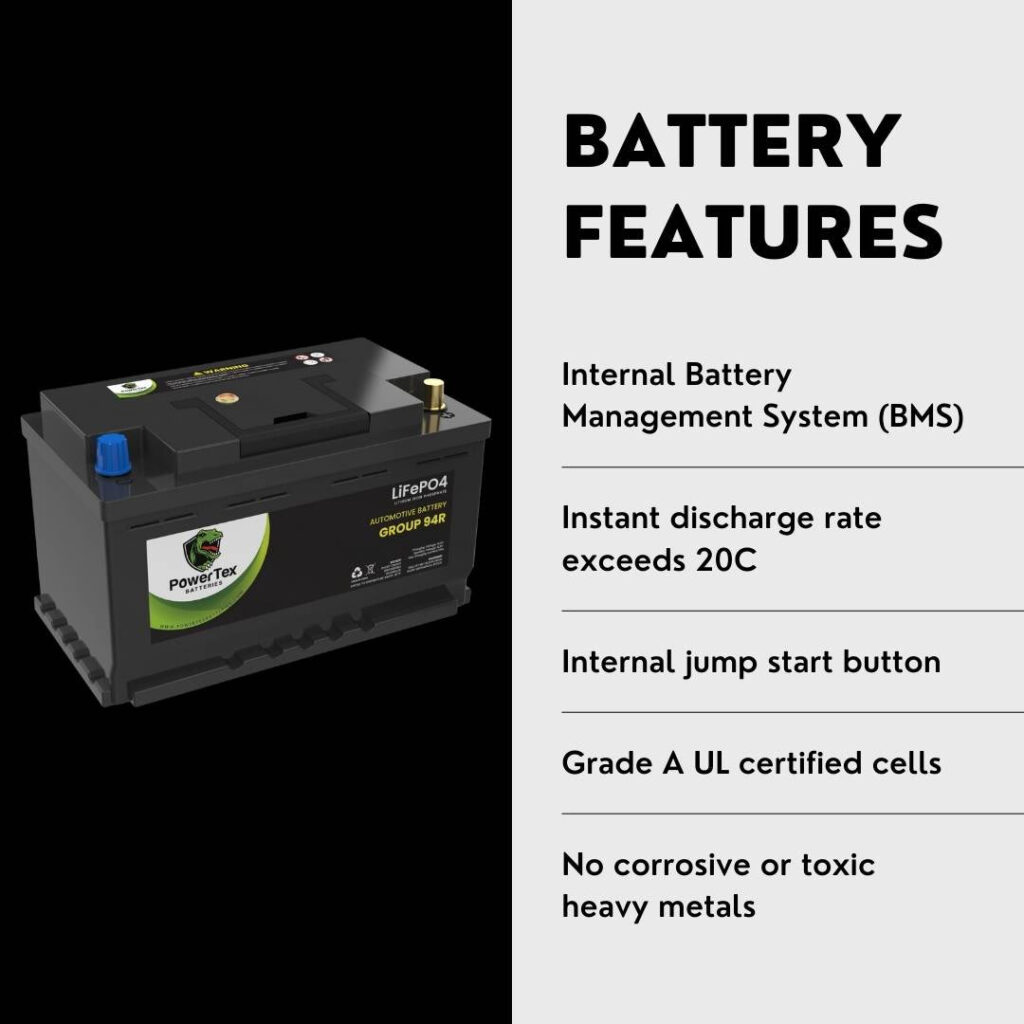

Certifications and Safety

The flagship product, the Gen. 1.1 Supercell, has obtained UN 38.3 and UL 1642 certifications, ensuring that the cells meet the highest safety standards. These certifications allow the company to safely transport the cells to its customers’ facilities. Forge Battery expects to ship thousands of cells in 2024 to its current customers, representing several GWh per year in confirmed orders.

Atomic Armor Technology

The cells of the Gen. 1.1 Supercell are equipped with Forge Nano’s proprietary Atomic Armor technology. This technology involves the deposition of ultrathin atomic layers that protect materials from undesirable chemical reactions. As a result, the cells offer a specific energy of 300 Wh/kg without compromising the cycle life of charge-discharge.

Advanced Materials and Performance

The Supercell uses a cathode made of nickel manganese cobalt lithium oxide (NMC 811) and an anode made of silicon composite graphite (SiOx). This combination allows the cell to exceed the energy density targets set by the United States Advanced Battery Consortium (USABC), while reducing the cost by 20% per kWh. The cost reduction is also facilitated by the decrease in electrolytes and electrolyte additives.

Target Markets and Development

The A-Sample from Forge Battery is currently undergoing life cycle testing to meet the specific needs of various markets, including electric trucks, off-road vehicles, motorcycles, aerospace, and applications for the Department of Defense (DoD). Barbara Hughes, VP of Energy Storage at Forge Nano, mentions that these cells surpass those currently on the market in terms of energy density and capacity.

Infrastructure and National Ecosystem

A Gigafactory will be established in 2026 near Raleigh, North Carolina, for the commercial production of Supercells. Forge Battery is committed to sourcing materials primarily produced in the United States, with 90% of the cell content coming from U.S. entities. Currently, 100% of the cathode and anode materials come from U.S. suppliers, with additional materials sourced from South Korea.

Summary List

| Technical Features | Advantages and Target Markets |

| Specific energy of 300 Wh/kg | Electric trucks, off-road vehicles, motorcycles |

| Atomic Armor technology | Aerospace, DoD applications |

| 20% cost reduction per kWh | Superior energy density and capacity |

Articles similaires

Thank you!

We will contact you soon.